3D Model to Make Collection

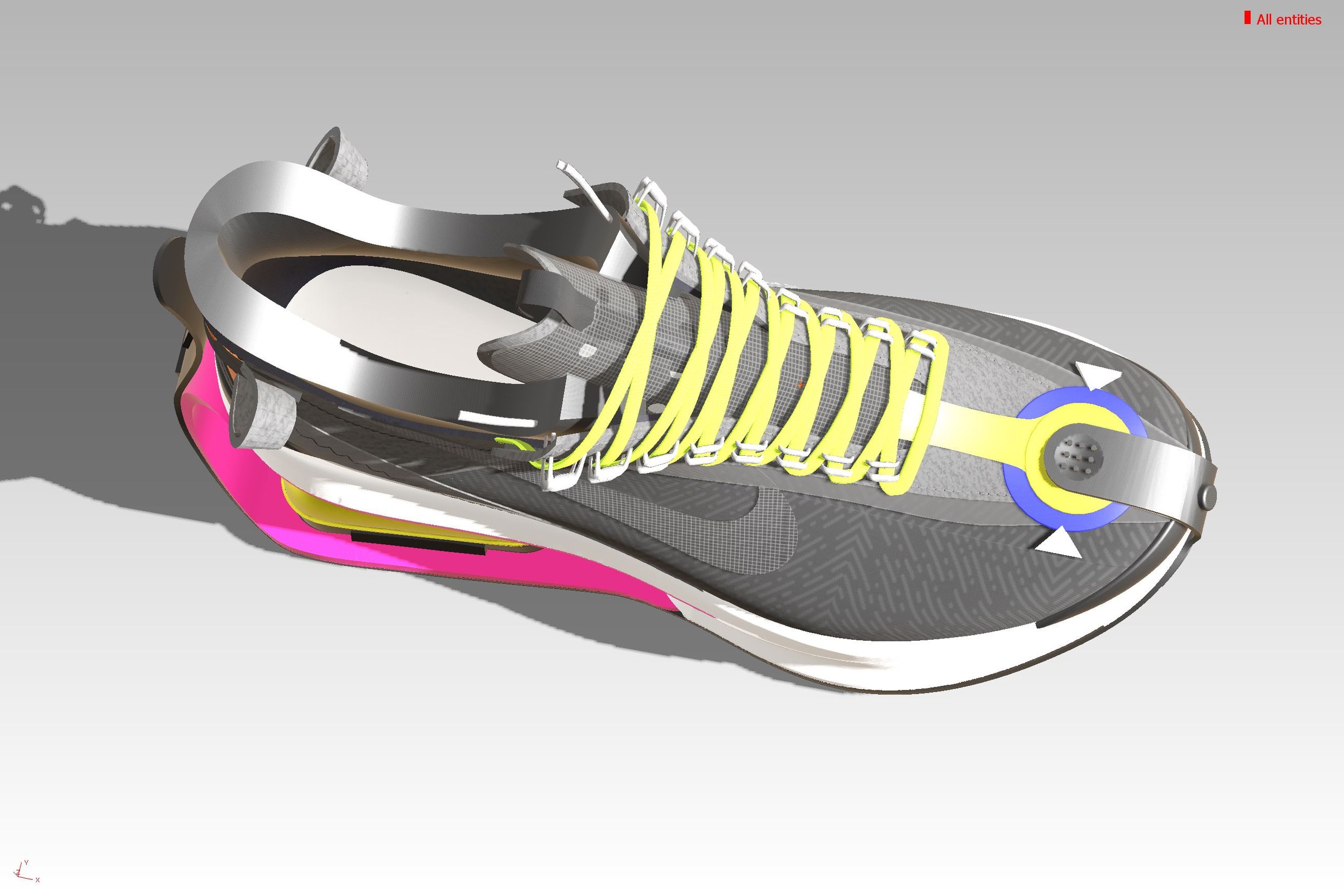

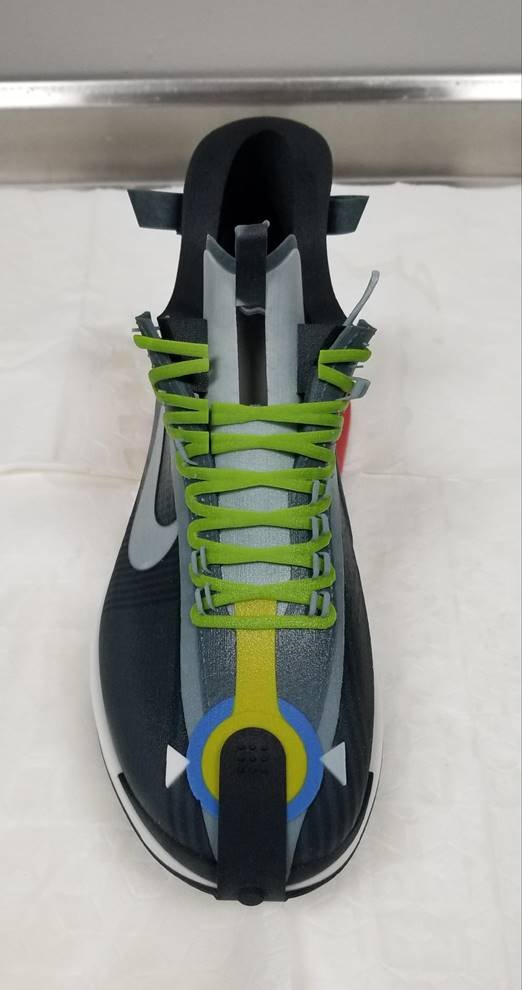

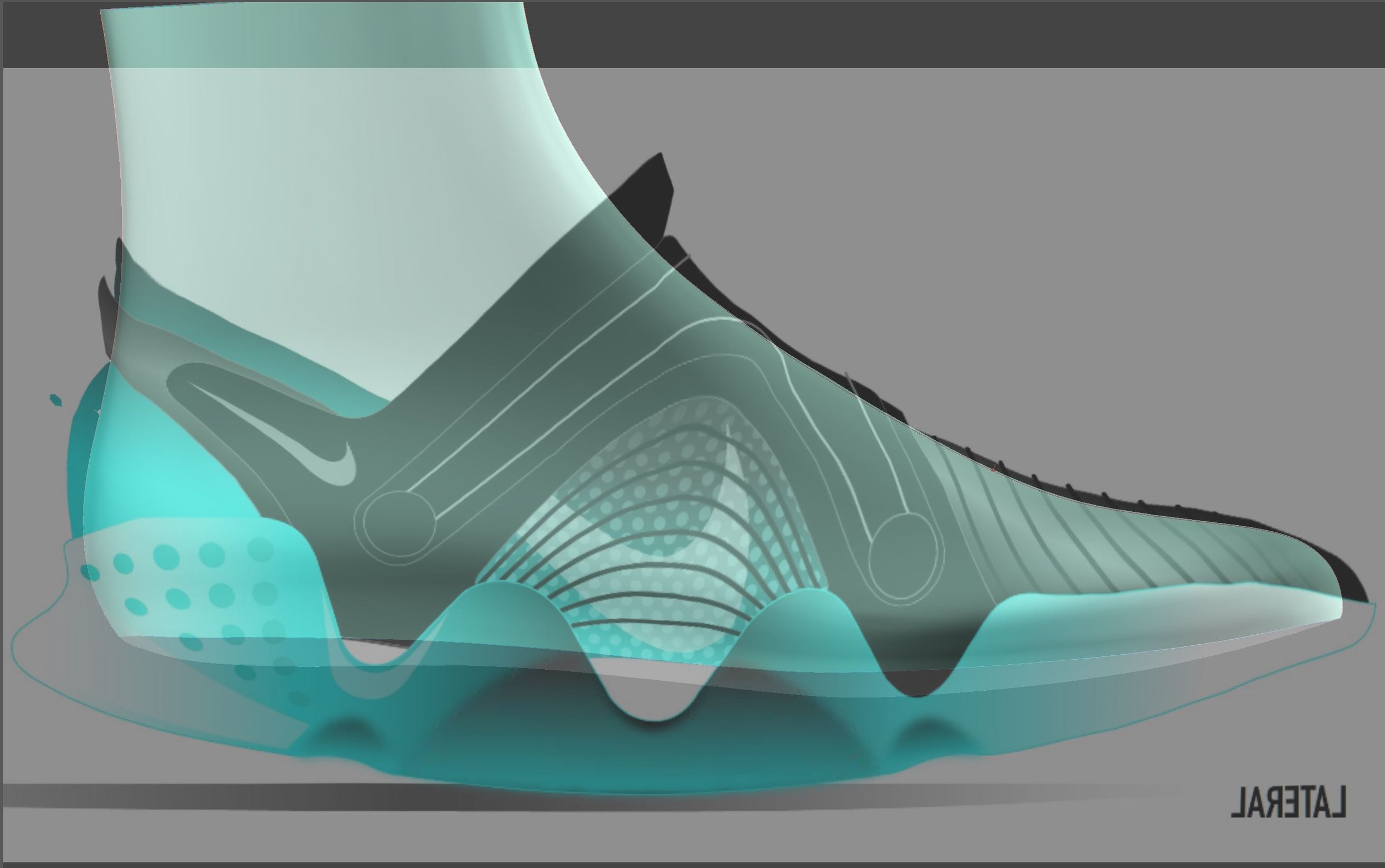

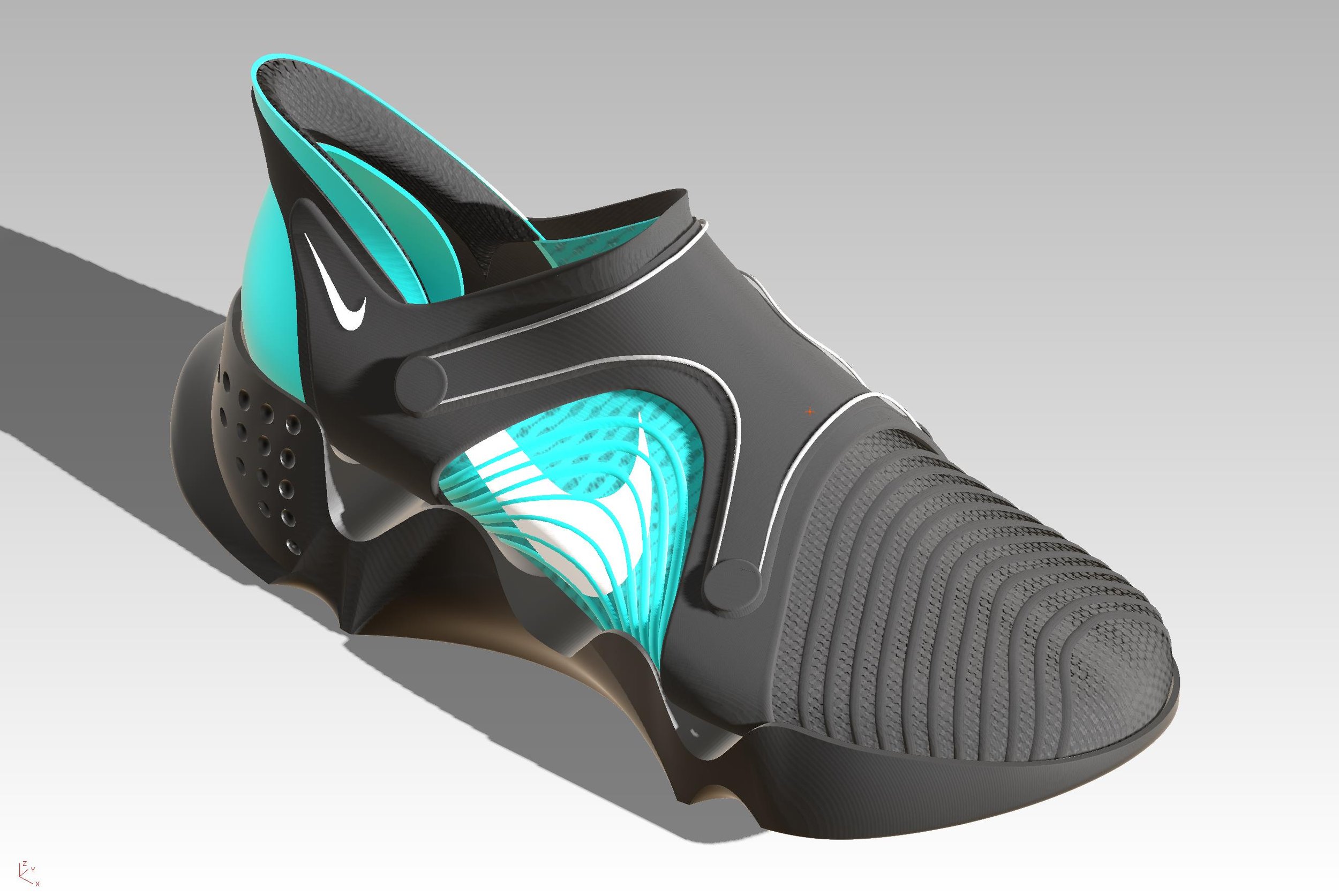

I can create a digital or physical footwear sample. My capabilities range across various footwear 3D software and 2D rendering software. From a digital model, I can create 2D patterns to output for generating parts, paper patterns and 3D printed components. I can stitch, last, sole lay and assemble the entire shoe together to create an actual physical sample.

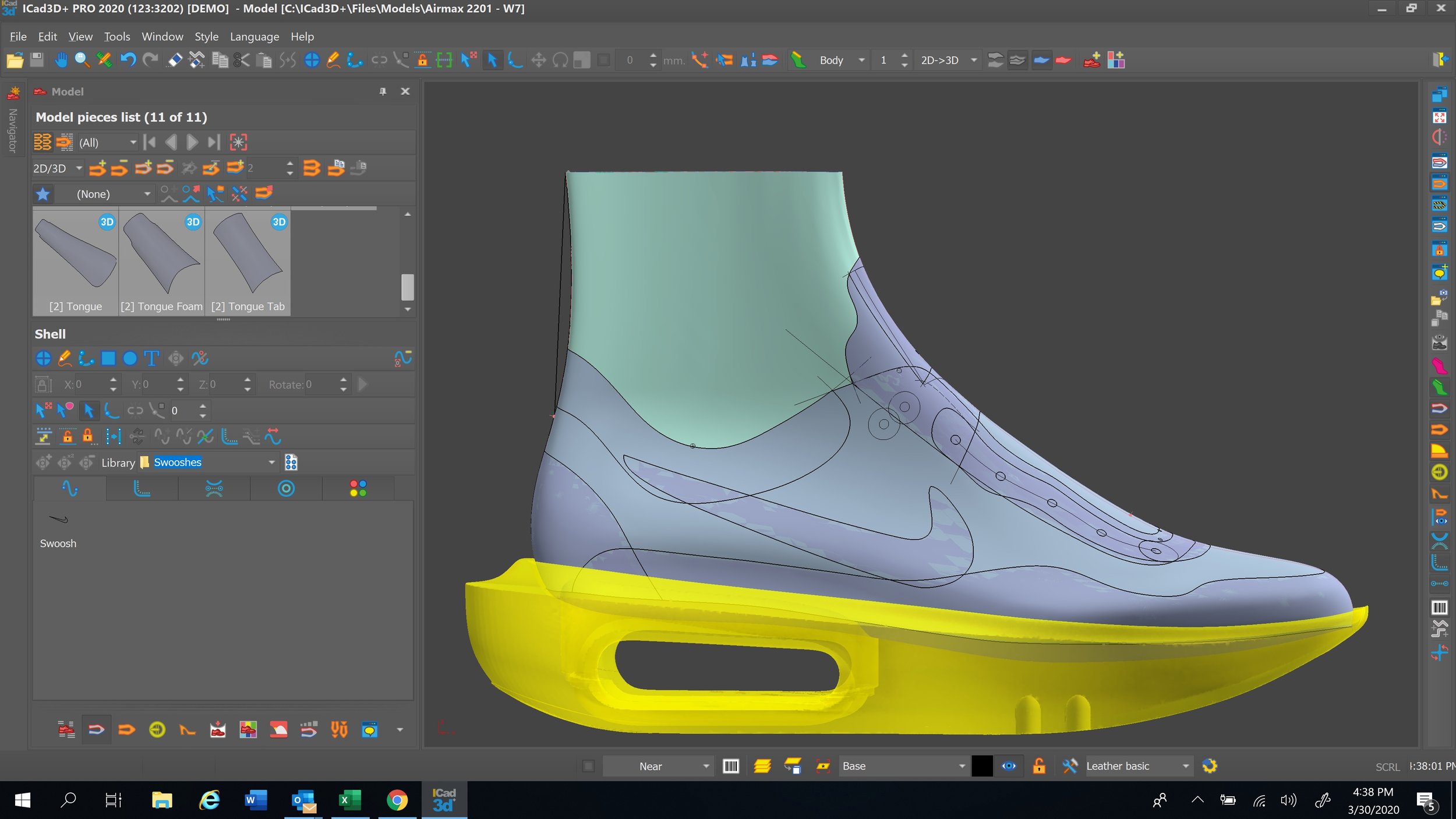

For two years, I tested iCad3D+ software, created training curriculum with Arsutoria for teaching Nike employees, while working with Nike Tech to validate the software’s cloud risk assessment and making sure Nike Legal set up the software vendor’s NDA and payments correctly. This was a heavy project to introduce to Nike Design, Nike 3D Designers, the Concept Lab, the CCC and the Footwear Prototyping Department to adopt iCad’s design to make capabilities.

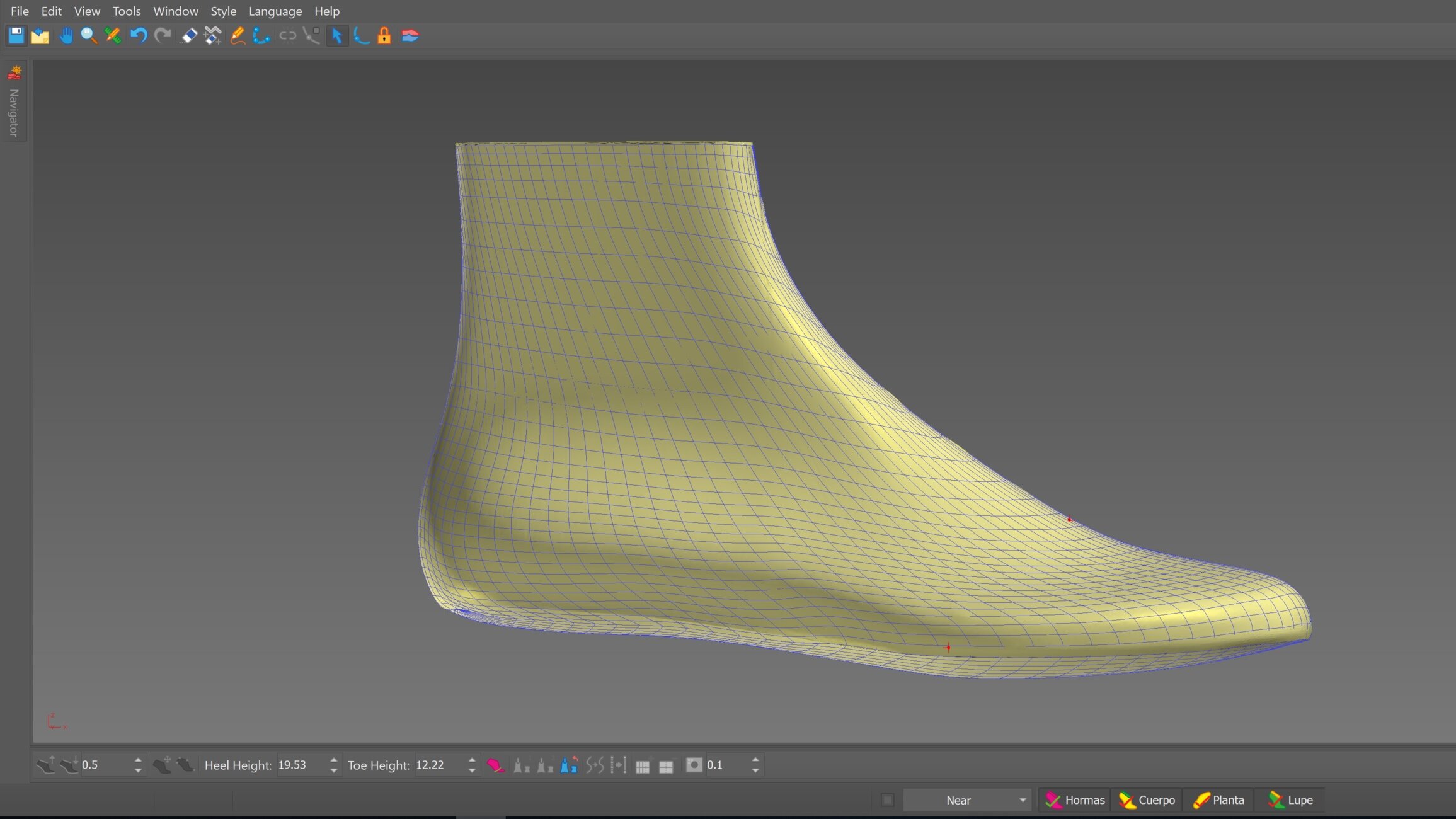

In iCad, I can digitally draft a last, apply a design and create 3D parts that correlate with 2D patterning. The model can be 3D printed, created into a movie and generated into a 3D rendering environment, such as a “Nike store shelf.” The parts can be flattened for patterning and sent to cutting machines for building a sample. Tooling, 3D components or hardware can also be generated in the software with the support of a Rhino plugin. This allows for a universal software and platform for everyone to work in without exporting various file types for project handoffs. Any design changes made in 3D update instantly in 2D and vice versa

Expertise

Software

iCad

ProCam Dimensions

Romans Cad

Crispin

3D Printing

SLS

Resin

MakerBot

Lutzbot

2D Patterning

Digital Drafting

Cutting Outputs

Paper Patterns

Material Cutting